Unlocking Market Agility with Flexible, Small-Footprint Manufacturing

Summary

Our research and strategic roadmap enabled rapid market testing, cost-efficient production, and resilient supply chain solutions.

Client challenge

A global snack manufacturer faced a critical challenge: how to produce short runs of snack products in regions where traditional large-scale plants were impractical. They needed a solution that combined flexibility, speed, and minimal infrastructure – without compromising product quality or brand standards. This capability was essential for testing new markets and building resilient supply chains in unpredictable environments.

Our approach

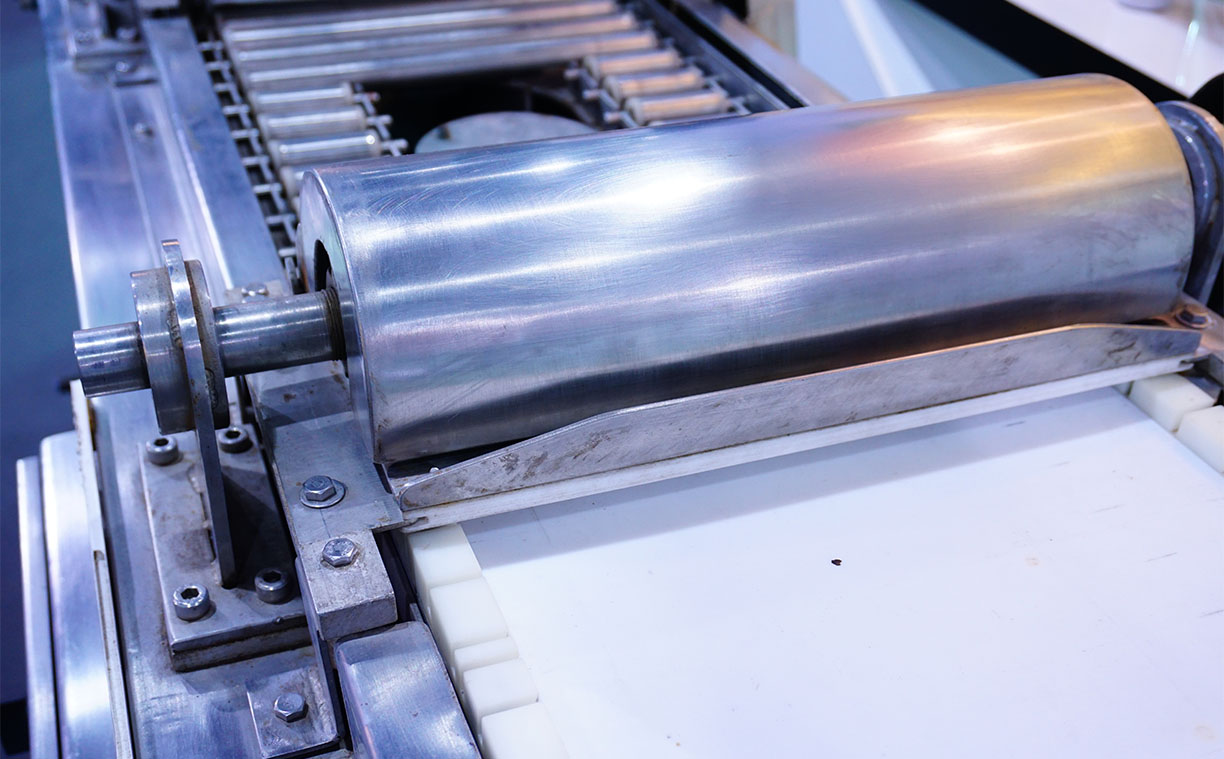

We began by mapping the entire snack production process to understand the technical requirements for small-scale manufacturing. Using this framework, we conducted a comprehensive scan of the market to identify emerging technologies and providers – from equipment manufacturers to systems integrators and turnkey solution specialists.

Working closely with the client, we filtered the findings to select nine high-potential technology partners for deep-dive evaluation. Each was assessed against critical criteria: ability to produce sellable products, geographic coverage, degree of automation, and intellectual property considerations. This rigorous process ensured that shortlisted solutions were not only technically viable but strategically aligned with the client’s growth objectives.

Client benefit

Our analysis delivered more than a list of suppliers – it provided a clear roadmap for implementing flexible manufacturing. Using our proprietary 2×2 decision matrix, our client could weigh internal versus external development models and determine the optimal level of involvement. The result was the development of a new capability that enables rapid market entry with minimal infrastructure. Our client can now test demand in new regions quickly and cost-effectively, reducing risk before committing to permanent facilities. This approach strengthens supply chain resilience, accelerates innovation, and opens new growth opportunities in challenging markets.

Consumer services

Discover the expertise we offer across the consumer market and how we collaborate to solve challenges through R&D

Expert insights

Explore our case studies to find out about our exciting work and read our latest insights and white papers authored by our industry leaders

Careers

Join our dynamic consultancy business to work in an exciting science and technology environment with leading global organisations.