Who can help us establish small footprint manufacturing in new markets?

We worked to help our client develop more flexible and less resource intensive methods of manufacturing, in order to test market response to its products and decide where to establish more permanent manufacturing plants.

Our client asked:

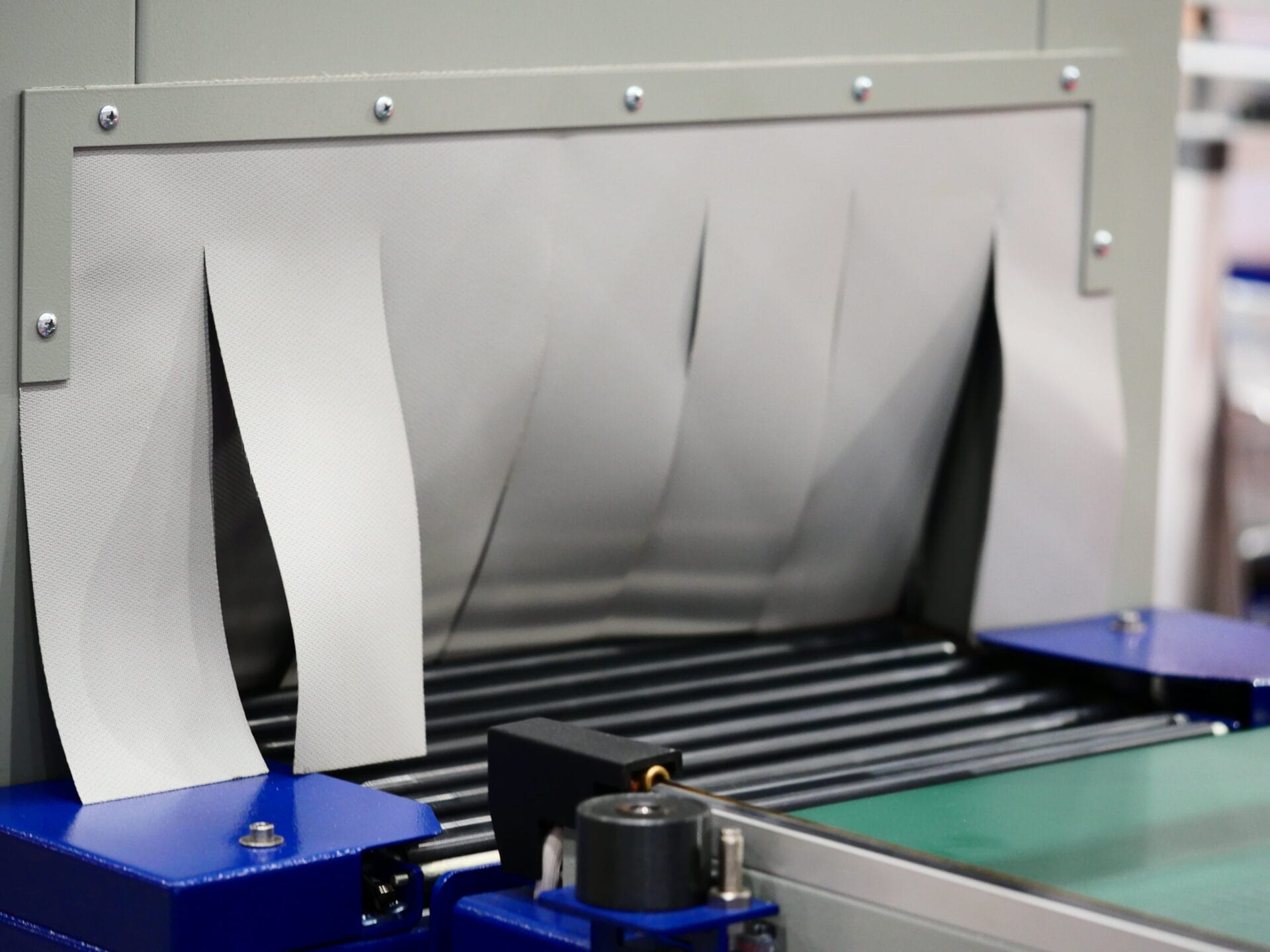

Our client was interested in building capability in flexible, small footprint manufacturing with the ability to produce short production runs of snack products in locations where traditional manufacturing methods are not viable.

The project story:

We generated a research framework based on snack processing steps and conducted research to populate a map of small-scale technology and technology providers, including equipment manufacturers, systems integrators, and solution providers.

We then worked with the client to filter the results from the research to identify nine technology providers for deep-dive profiling, including a focus on the ability to produce sellable product, geographical coverage, degree of automation, and intellectual property.

Results: deliverables and outcomes

Our client was better able to understand the requirements needed to provide flexible small footprint manufacturing capabilities for their snack products because of our work.

Our flexible manufacturing approach – 2×2 matrix focuses on level of involvement (high vs low) and development model (internal vs external) – helped our client to decide which methods they wanted to pursue.

The new flexible manufacturing capability has allowed our client to operate in new regions with minimal infrastructure, enabling them to test markets and establish whether it’s financially viable to build more permanent manufacturing plants.

Industrial markets

Discover the expertise we offer across the industrial market and how we collaborate to solve challenges through R&D.

Innovation services

Find out about Sagentia Innovation’s comprehensive suite of advisory and product development services, tailored to support consumer and industrial sectors.

Contact us

We’d be delighted to discuss your challenges and explore how innovative thinking could help solve them. If you’d like us to get in touch, please complete the contact us form.