High water use in cleaning systems is a growing concern for many manufacturers. Whether mixed with chemicals for washing, heated for sanitation, converted to steam for sterilisation, or used to rinse residues, water plays a vital role. So what can be done to minimise cleaning systems’ water consumption without compromising their performance? Various industries, from pharmaceutical and home/personal care to food, beverage, and dairy, are facing this challenge. We set out to explore the options from a science and engineering perspective.

Vortex rings: harnessing fluid mechanics for clean-in-place (CIP) systems

Our initial analysis of CIP systems used in manufacturing identified the rinse phase following wash cycles as an opportunity to innovate. We then moved onto ideation and concept development, landing on vortex rings as having high potential for certain applications.

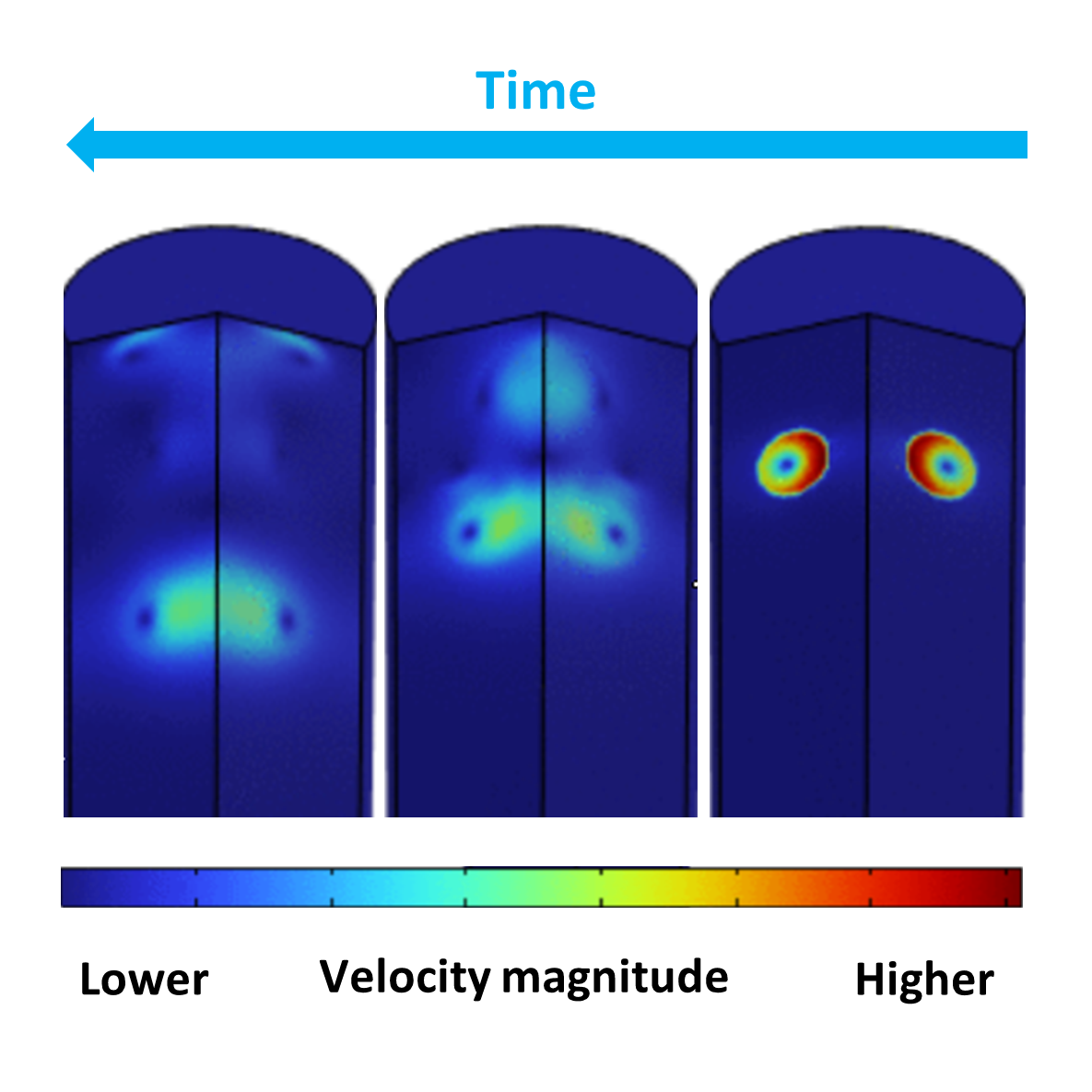

Vortex rings are a naturally-occurring phenomenon seen in fluids (liquid or gas). Perhaps the most striking example is dolphins blowing vortex rings of air into water, which they chase, push, swim through, and play with. Self-propelling and long-lived, vortex rings can travel several metres in some circumstances1. This, combined with high internal rotational velocity, presents vortex rings as a relatively simple way of generating and propagating agitation through a medium. A vortex ring is a torus (‘doughnut’) fluid structure which travels forward by rotating within itself. Think of a water snake toy, which slips through your hands as you try to hold it.